competence center for all aspects of EV charging technology

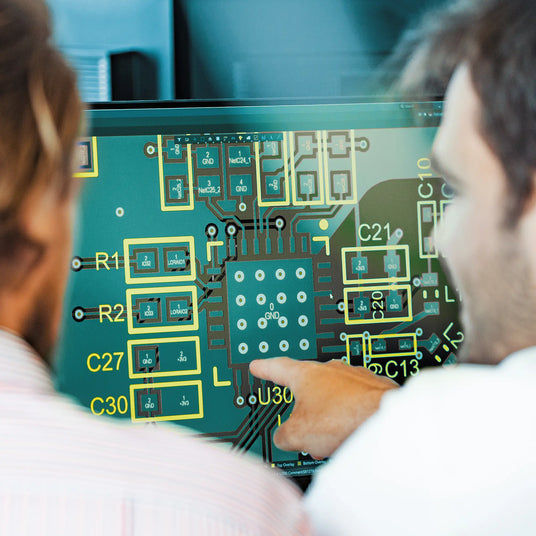

An interdisciplinary research and development team of experienced specialists in the areas of software, hardware, engineering and design works under one roof. Juice Engineering develops product adaptations and derivatives, white label solutions, components and complex software integrations for global customers in the shortest possible time.

Intelligence, ingenuity, innovation

We always develop our solutions from the user's perspective - from the basic components to the finished overall concept. We achieve this perfection by permanently optimizing our processes and continuously improving our products. Because quality is not created by the combination of individual, prefabricated components, but by the interaction of teams of specialists.

Interdisciplinary approach for holistic development

Our customers and partners benefit from the wealth of experience of our diverse teams of highly qualified specialists.

JUICE Engineering

-

designer pool

-

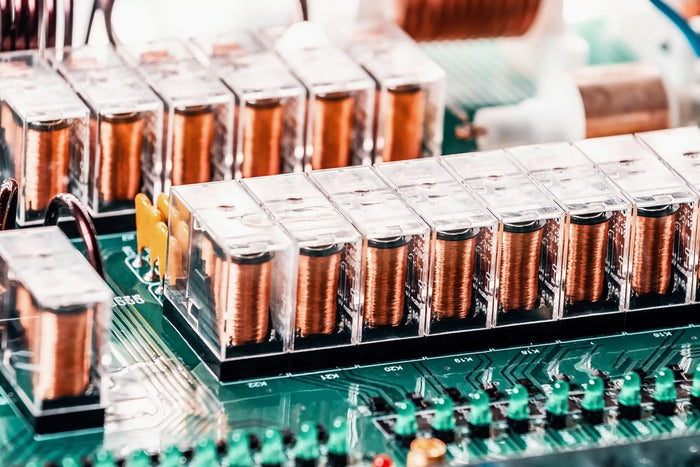

RCD Technology

-

EMV Labs

-

Communication Transmission

-

Hardware Specialists

-

ZHAW University

-

software engineers

-

Future Analysts

-

Mechanical Design Engineers

-

UI Specialists

-

Data Analysts

-

Do you want to shape the future with us?

solutions tailored to your personal needs

Systems that are optimally tailored to individual customer needs down to the last detail create perfection. What do you need to implement your project? Benefit from tailor-made solutions or adaptations of the successful and globally proven Juice hardware and software.

Technical innovations from Juice

Groundbreaking developments make Juice the market leader. What counts here is not what is feasible, but what brings real benefits to the customer.

-

![]()

adapter detection

The JUICE CONNECTOR is a compact plug connection developed by Juice that transmits not only power but also important control and temperature signals as well as the CP signal. As a proprietary interface, it connects all Juice adapters, extension cables and extensions to one another. Thanks to its drive-over safety of up to 3 tons and its waterproofness according to IP67, it is extremely robust and reliable in use.

-

![]()

Controlled load shedding

While conventional shutdowns can cause potentially dangerous damage due to sparking when the grid is overloaded, our technology ensures that the charging power is reduced safely and gradually. This pauses the charging process before critical loads arise - maximum protection for the vehicle, charging station and home installation.

-

![]()

temperature sensor

Household sockets are designed for everyday use, but charging an electric vehicle can put a lot of strain on them. Older sockets in particular are prone to overheating. The patented JUICE CELSIUS temperature sensor monitors the supply line and interrupts the charging process if it overheats. After cooling down, charging is automatically continued up to three times. If it gets too hot again, the charging cycle stops completely.

The right partner for bulk buyers.

Products specifically for business use.

Juice offers research, development, adaptations and components for the entire spectrum of charging technology. The engineering team is a pioneer in terms of design, feel, quality and user interface. All Juice products are characterized by their reliability and future-proofing.

Your benefits

Our products are designed from the ground up so that they cover a wide range of possible applications even in their standard version. Individual adjustments are therefore usually only necessary to a minor extent. This ensures rapid deployment within the project.