Why REACH, RoHS and Co. are more than bureaucracy

In addition to the social dimension and ethical concerns, environmental protection is also part of corporate responsibility. Its importance should not be underestimated, especially in the automotive sector, where countless materials are processed into a final product. This naturally also applies to electromobility and, in particular, to charging station manufacturers as part of the industry. Suppliers to OEMs must consistently ensure environmentally friendly processes and compliance with legal requirements, from material selection to the finished product. The framework for this is provided by directives such as REACH, RoHS, the Conflict Minerals Regulation, and the IMDS materials database system. But what does this mean in concrete terms? A look behind the scenes.

REACH: Chemicals under control

Background: The EU REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) has been the central instrument for protecting people and the environment from harmful chemicals since 2007. It was created because a growing number of studies demonstrated that numerous industrial substances are persistent, toxic, or hormone-disrupting—and thus enter the environment via air, water, or waste.

The principle: Dangerous substances such as bisphenol A or so-called “forever chemicals” such as per- and polyfluorinated alkyl compounds (PFAS) may neither be contained in the product nor used in the production process – even if they would offer technical advantages.

In practice: The European Chemicals Agency (ECHA) regularly publishes lists of critical substances. In electrical engineering, for example, this applies to PFAS, which are very effective as release agents in soldering, but at the same time are extremely difficult to degrade and pose a significant environmental burden. To comply with REACH, manufacturers must resort to alternative processes, even if these are more complex or expensive.

And Juice? Juice avoids PFAS and obtains appropriate confirmations from its suppliers.

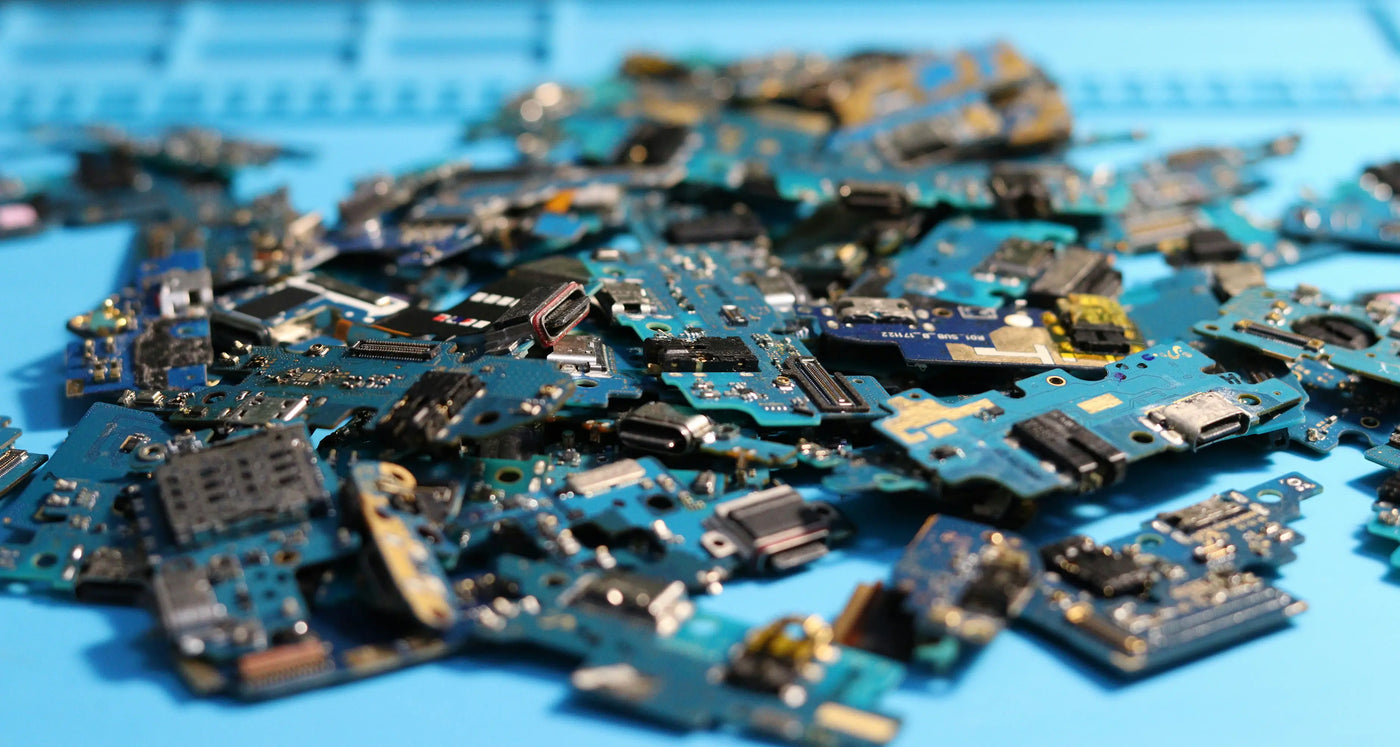

RoHS: When electronics should stay clean

Background: The RoHS Directive was introduced in 2003 in response to growing mountains of electronic waste and the release of toxic substances during their disposal. Heavy metals and brominated flame retardants were particularly in focus. The goal was to contain health and environmental risks during the production of devices.

The principle: Electronic devices may only contain certain hazardous substances such as lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr VI), and certain flame retardants such as polybrominated biphenyls (PBB) or polybrominated diphenyl ethers (PBDE) below strict limits. These regulations are regularly updated.

In practice: An early example is the ban on lead in solder. Lead made solder joints pliable and facilitated the manufacturing process due to its good flow properties. Without lead, joints are more brittle and fragile. The switch to lead-free solder required shortening of soldering times due to the higher soldering temperatures required to avoid excessive stress on sensitive components.

The elimination of brominated flame retardants in housings and cables meant that alternatives had to be found that were safe and flame-retardant, but did not leave behind toxic residues.

And Juice? With the CE declaration of conformity, Juice confirms RoHS compliance.

Conflict minerals: responsibility in the supply chain

Background: Some minerals originate from regions where their mining occurs under exploitative conditions or finances armed conflict. In 2017, the EU therefore introduced the Conflict Minerals Regulation to strengthen transparency and accountability in global supply chains.

The principle: Raw materials such as tantalum, tungsten, gold or tin (3TG) may only be obtained from verifiably conflict-free sources.

In practice: In electronics, in addition to gold, which is used in circuit boards due to its conductivity, tin is particularly crucial for soldering processes. Purchasing tin exclusively from certified smelters can result in higher material costs, but it ensures a transparent supply chain.

And Juice? Juice sources its tin exclusively from one of the five smelters monitored by the Responsible Minerals Initiative (RMI). To ensure this, Juice must regularly obtain supplier reports and periodically issue proof of origin to customers.

IMDS: Material transparency for the automotive industry

Background: The International Material Data System (IMDS) was developed in the 1990s by leading car manufacturers to ensure compliance with environmental and safety standards across all supply chains.

The principle: Every material used in automotive production must be recorded in the IMDS database – from metals to plastics to coatings.

In practice, for a charging cable, for example, this means that the copper conductor, insulation, and sheathing are documented separately. If a particular plastic no longer meets current regulations, it is replaced and the change is recorded in the system. This allows manufacturers to track which materials were used at any time.

And juice? The JUICE BOOSTER 2, for example, is listed in detail in the IMDS – from the casing and circuit board to the cable and display. Every substance is broken down, including any chemicals like TBBPA, which are subject to separate regulations (e.g., California Proposition 65).

As a Tier 1 supplier for OEMs, Juice requires its suppliers to declare all components. The information for each component must be passed down the supply chain. This way, Juice not only fulfills legal obligations but also the high standards of OEMs such as Mercedes, BMW, and GM.

Conclusion: Environmental protection with a sense of proportion

These regulations are not a bureaucratic obstacle, but a safety net for people and the environment. They help ensure that products not only function technically, but are also sustainable in their production and disposal. Some requirements may seem restrictive at first glance, but they often prove to be drivers of innovation – from cleaner processes to new materials to more durable products.

Environmental protection doesn't have to slow progress. The example of JUICE BOOSTER 2 demonstrates that high-tech can be developed and manufactured responsibly. This transforms regulations into a quality feature that benefits not only customers but ultimately the entire industry.

Read more here

-

ISO 20400 – Sustainable Procurement | Juice Technology AG

Learn how the international standard ISO 20400 supports companies in responsible procurement. -

What exactly are "rare earths," and are they even contained in electric car batteries? | Juice Technology AG

A fact check on rare earths and their actual role in electromobility. -

Car manufacturers' developments: Will they soon be free of cobalt and rare earths? | Juice Technology AG

An overview of current trends in battery development and alternatives to critical raw materials. -

Greentech Award: Juice honored for innovation

Juice Technology is recognized for pioneering contributions in the field of sustainable technology. -

JUICE CHARGER me wins Green GOOD DESIGN Award 2022 | Juice Technology AG

The compact home charger impressed the jury with its design and sustainability. -

Over 332 football fields reforested for more sustainable mobility | Juice Technology AG

A strong reforestation project from Juice actively contributes to a greener future.